|

Wet sanding with 400 grit, then 1000 grit before hitting it on the buffer. Finished the black oxide treatment on the rear hardware, and I think it turned out pretty good.

1 Comment

The first picture is after soaking in Evapo-Rust. The second is after blasting. The last pictures are after the black oxide treatment. All the old hardware that I am using will get this same treatment. Almost looks painted.

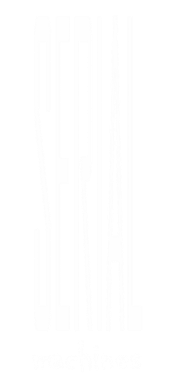

Now I can finish port matching the heads, and finish the accessory brackets. U-joints and rod ends turned out pretty good after paint. Still working on getting the aluminum rear end components polished and re-assembled.

Started soda blasting aluminum parts today. Looks like everything should turn out pretty nice once I get it all polished. Should be painting rod-ends, bearings, and u-joints tonight. Tomorrow I will continue blasting and start cleaning drive yolks and caliper pucks.

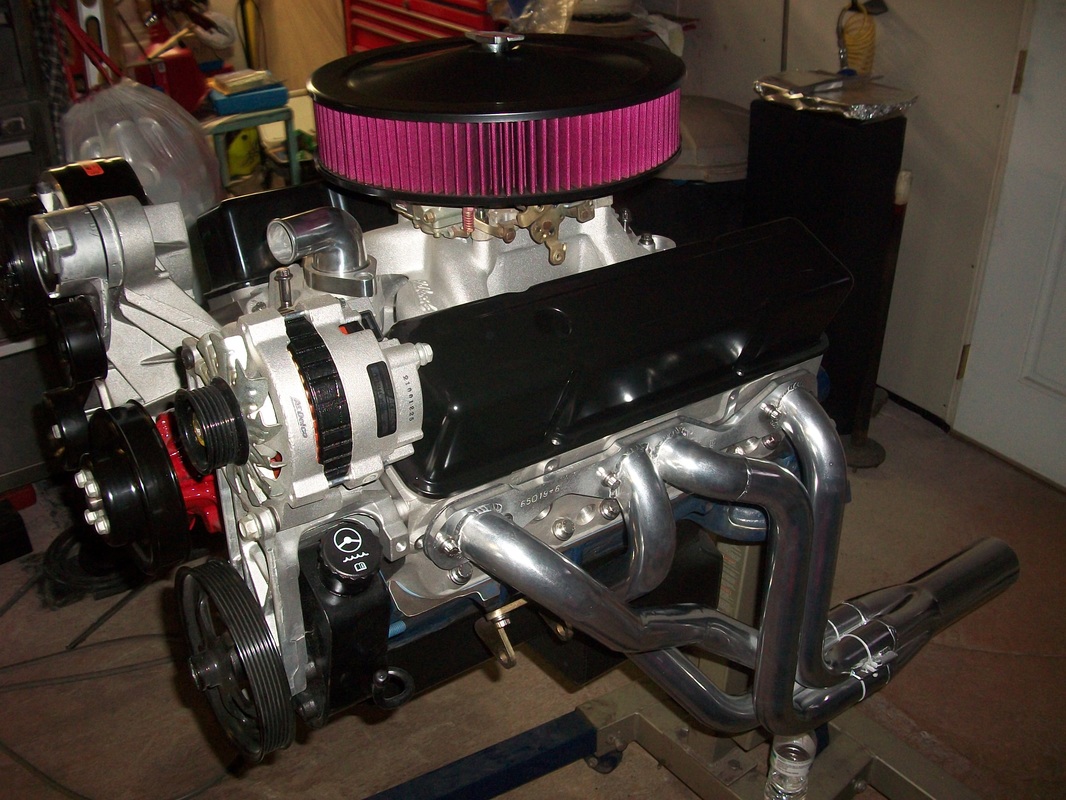

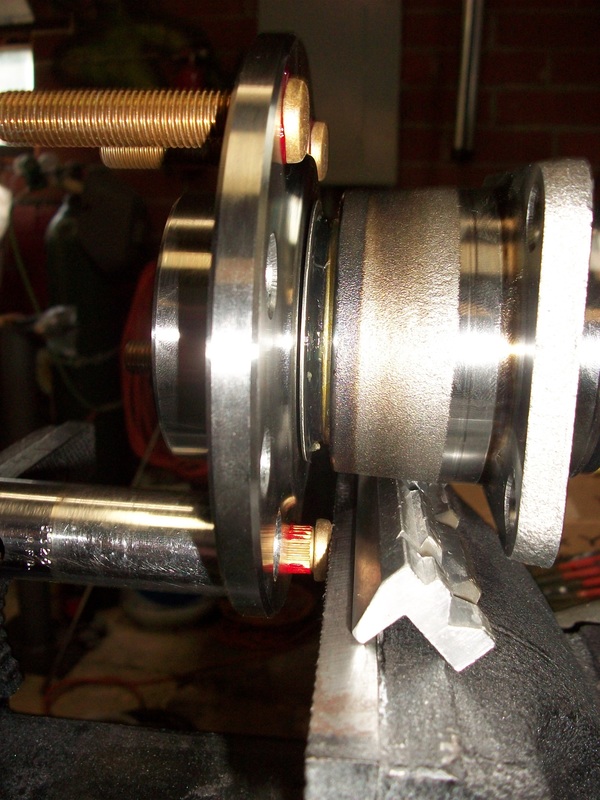

Finished the tedious aluminum grinding over the weekend. I still have a couple of drive-train pieces to grind, but they are not nearly as intricate. Next step is to soda blast, wash, and polish. Unfortunately when I got the blasting box out this weekend I noticed that the gloves had rotten away. A new pair should be here in the next day or so. Today I managed to get the old wheel studs out of the wheel bearings, and press the new ones in. Turns out I had to ream every hole to get the proper press fit. Just a little bit of paint and they are ready to assemble.

|

Serial Machines

2711 Mooresville Rd Archives

May 2017

Categories |

|

|