|

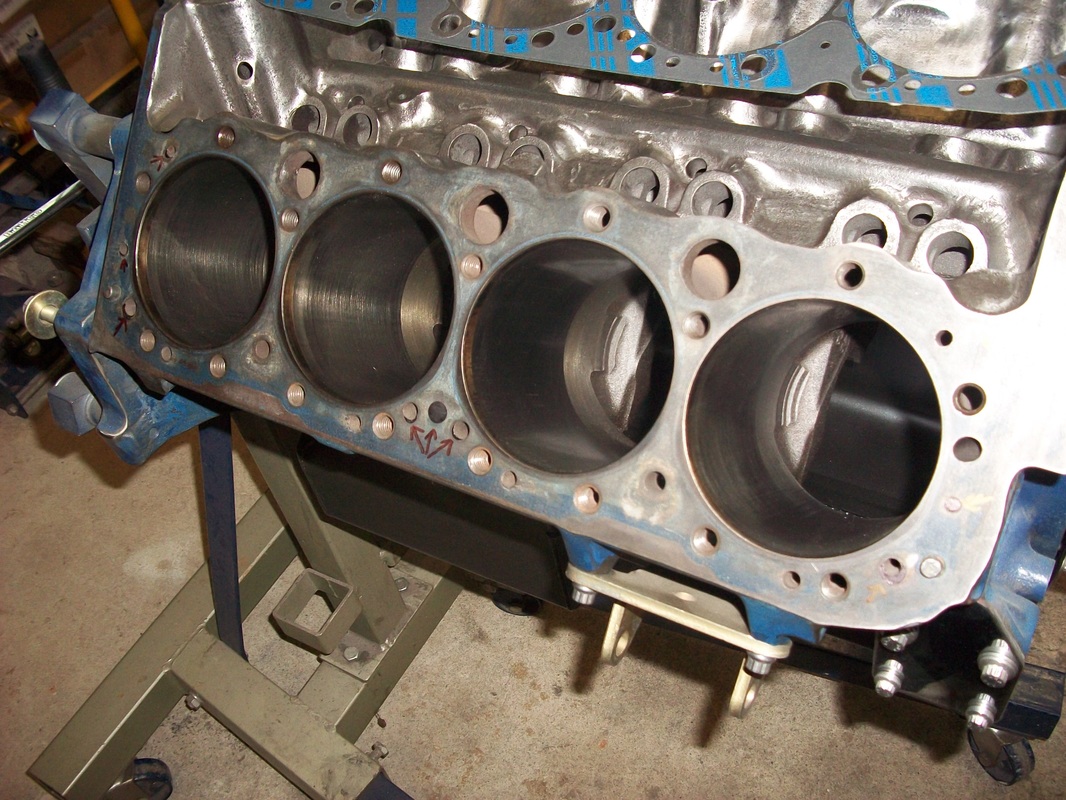

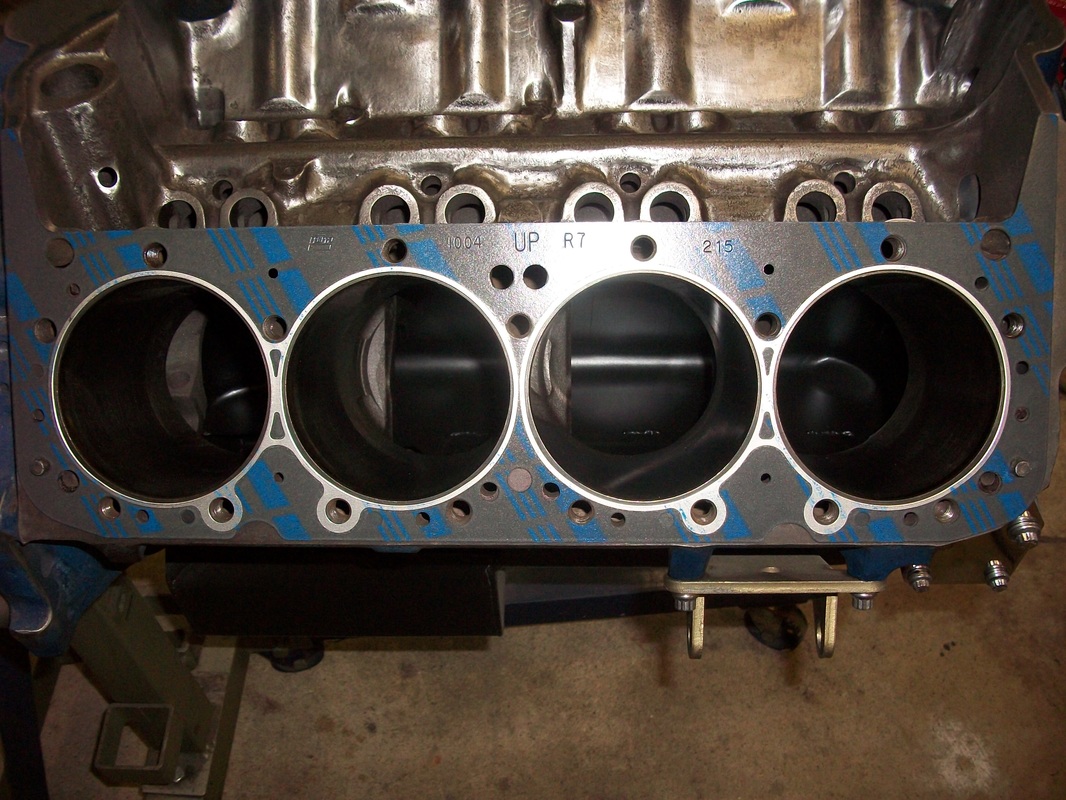

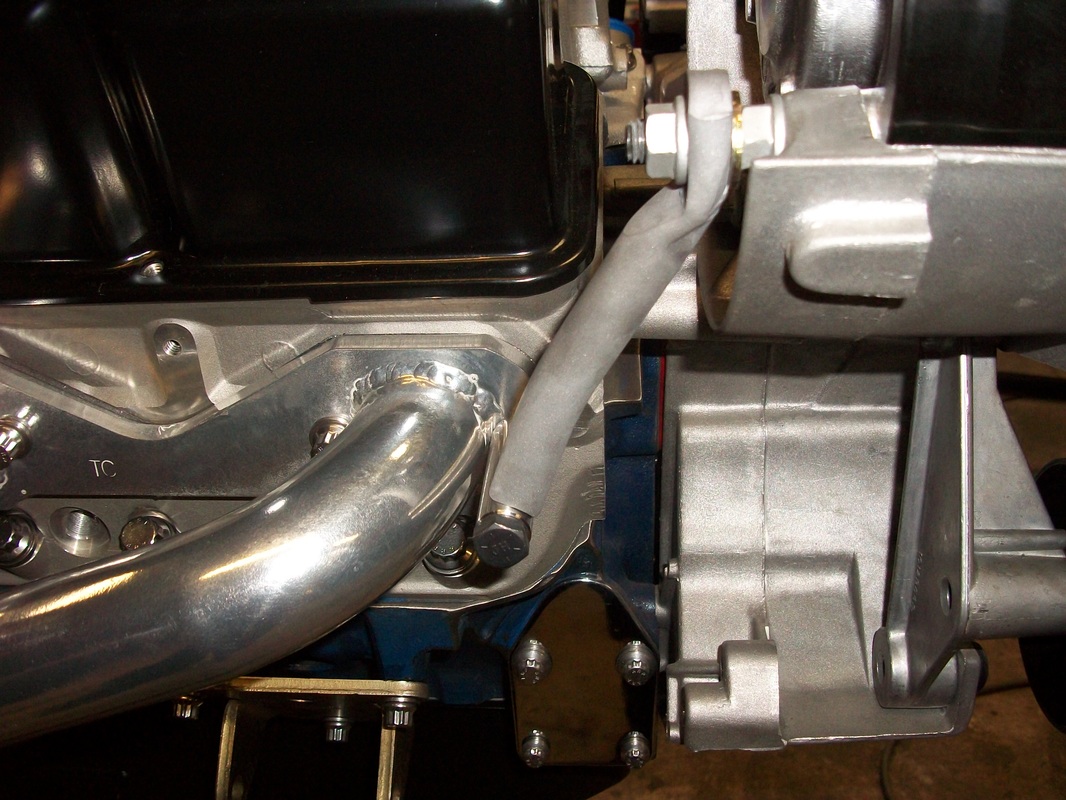

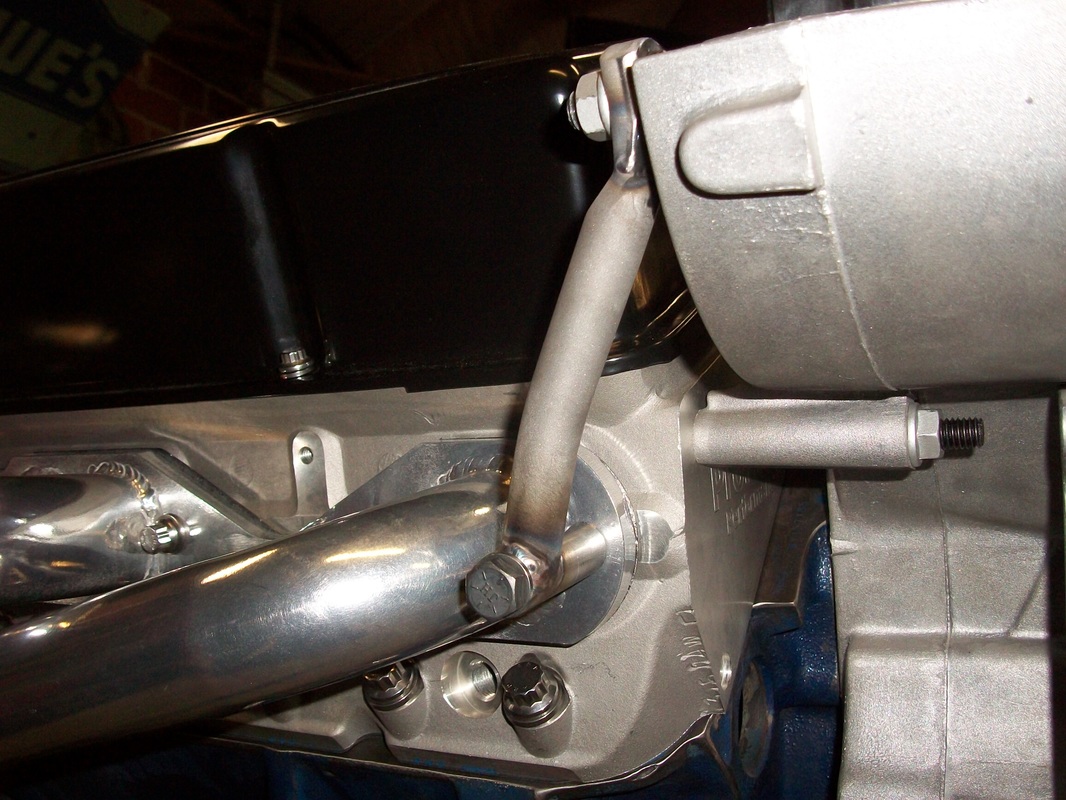

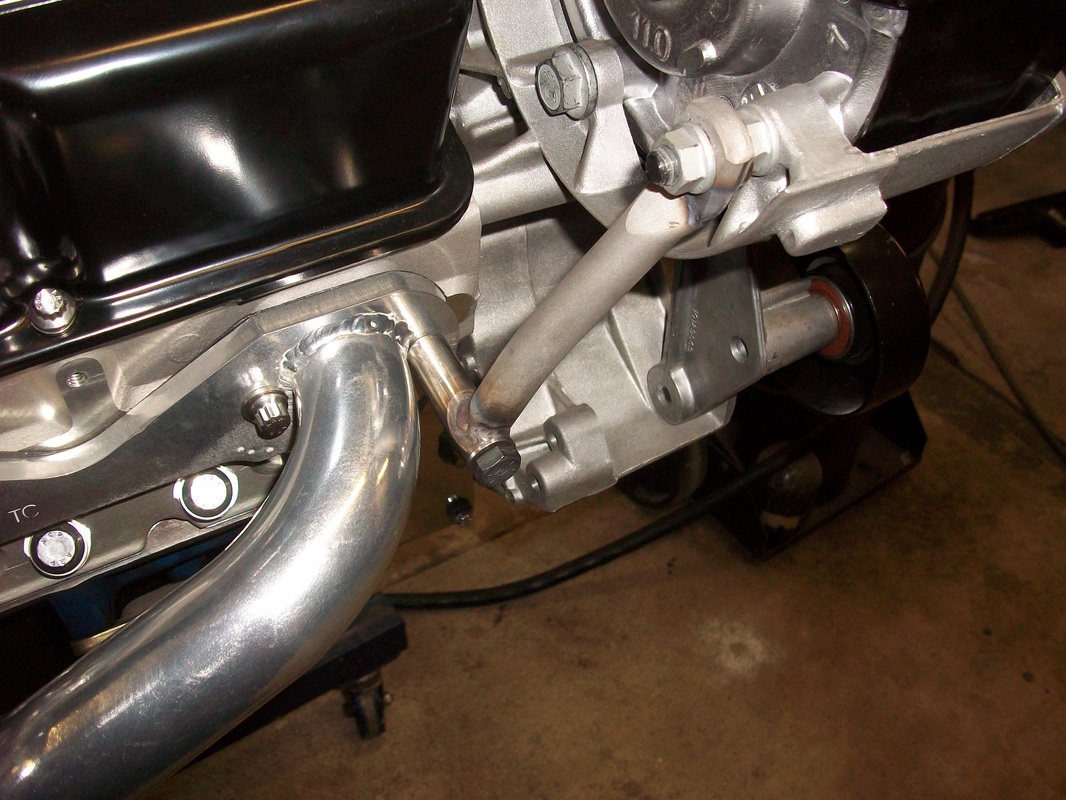

I've been back at it for a couple of days now. All the drive shafts and brake calipers are reassembled. I also finished all the modifications on the engine block, so it is ready to go to the machine shop. Started working on the bat wing and pumpkin this morning. I will have to fabricate some sort of case spreader in order to properly set up the differential.

0 Comments

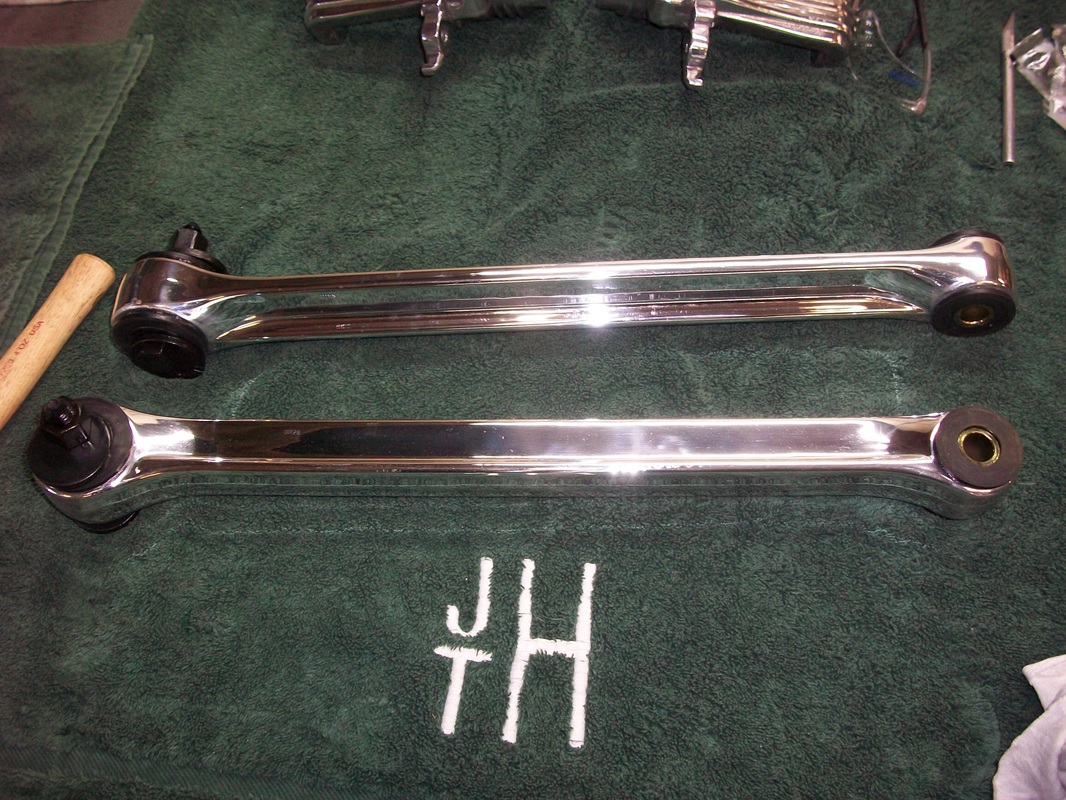

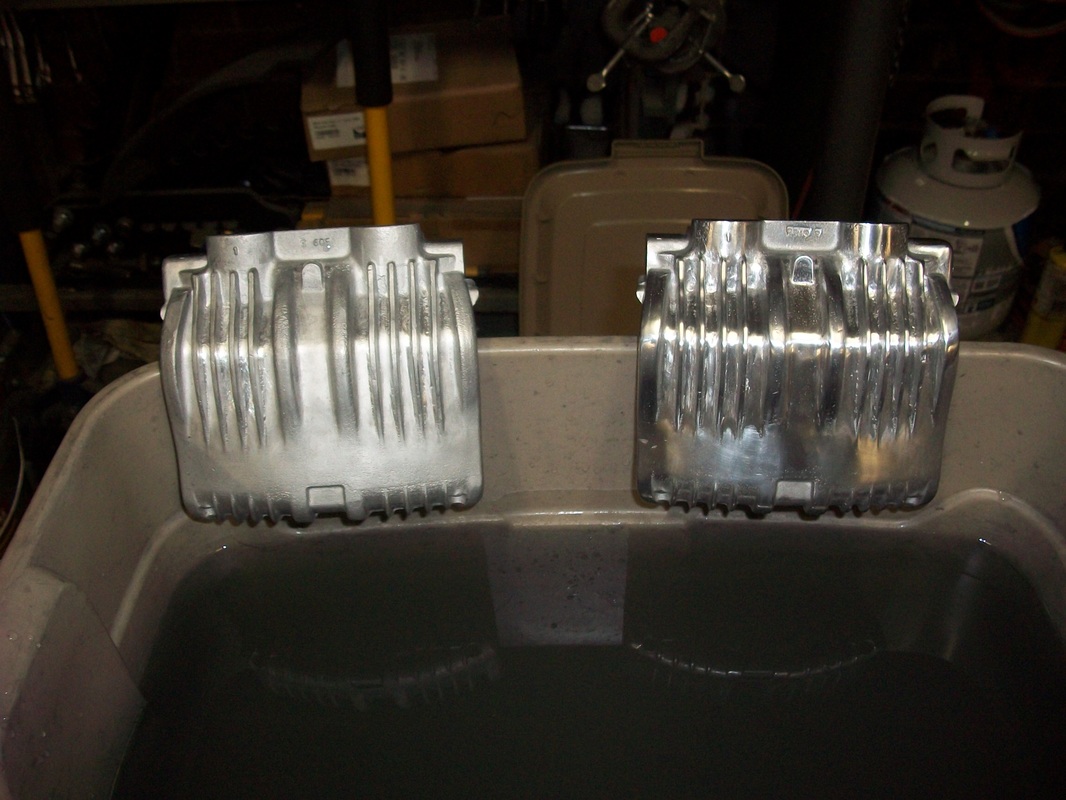

Trying to finish up polishing so I can make room to work on the old lady's car this weekend. Finally buffing with the white diamond. I have found it is difficult to take a picture of a mirror with this camera.

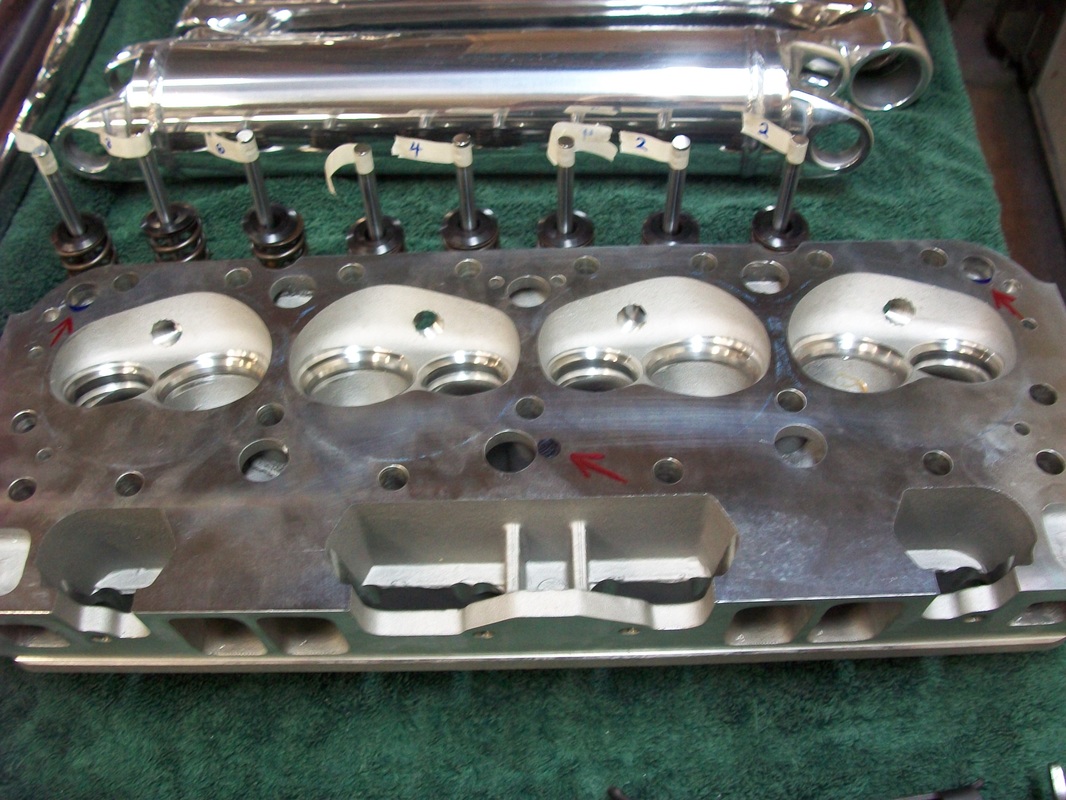

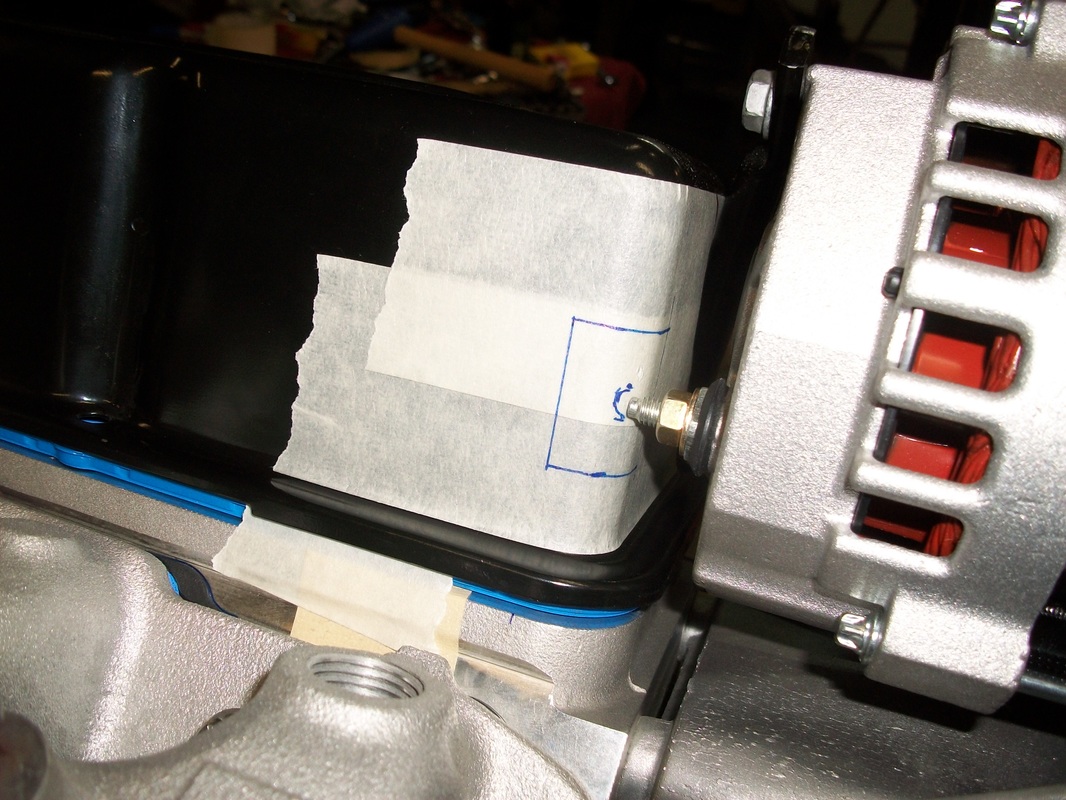

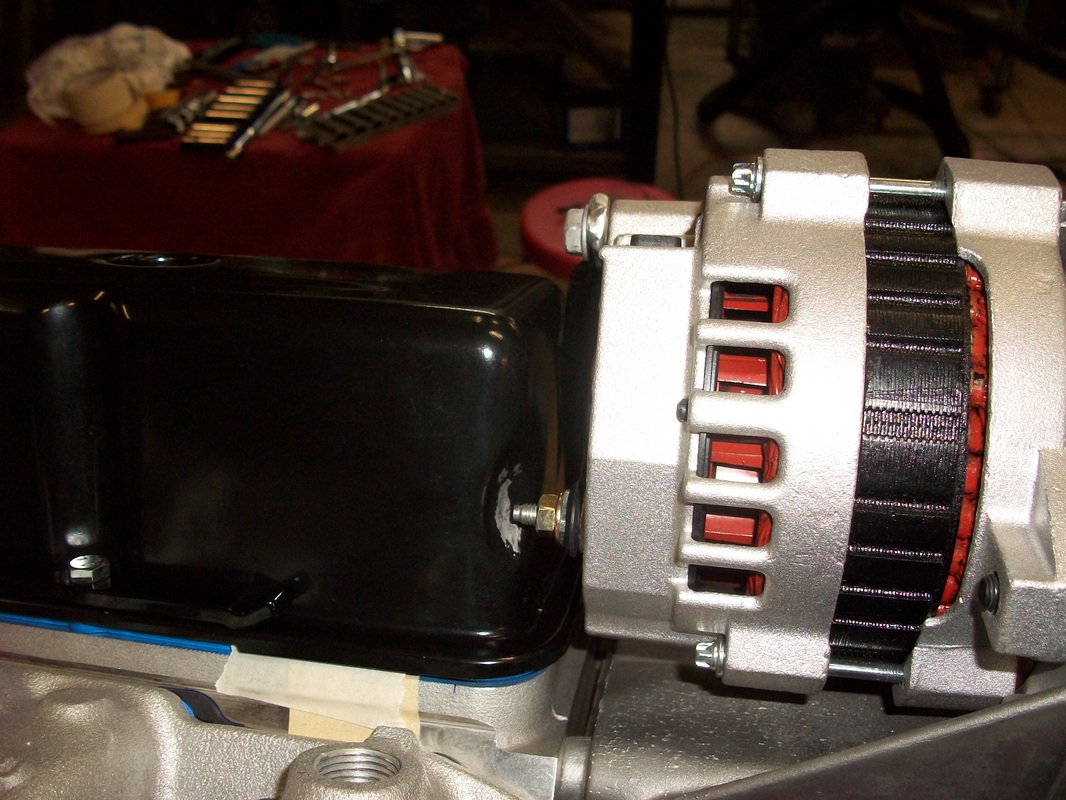

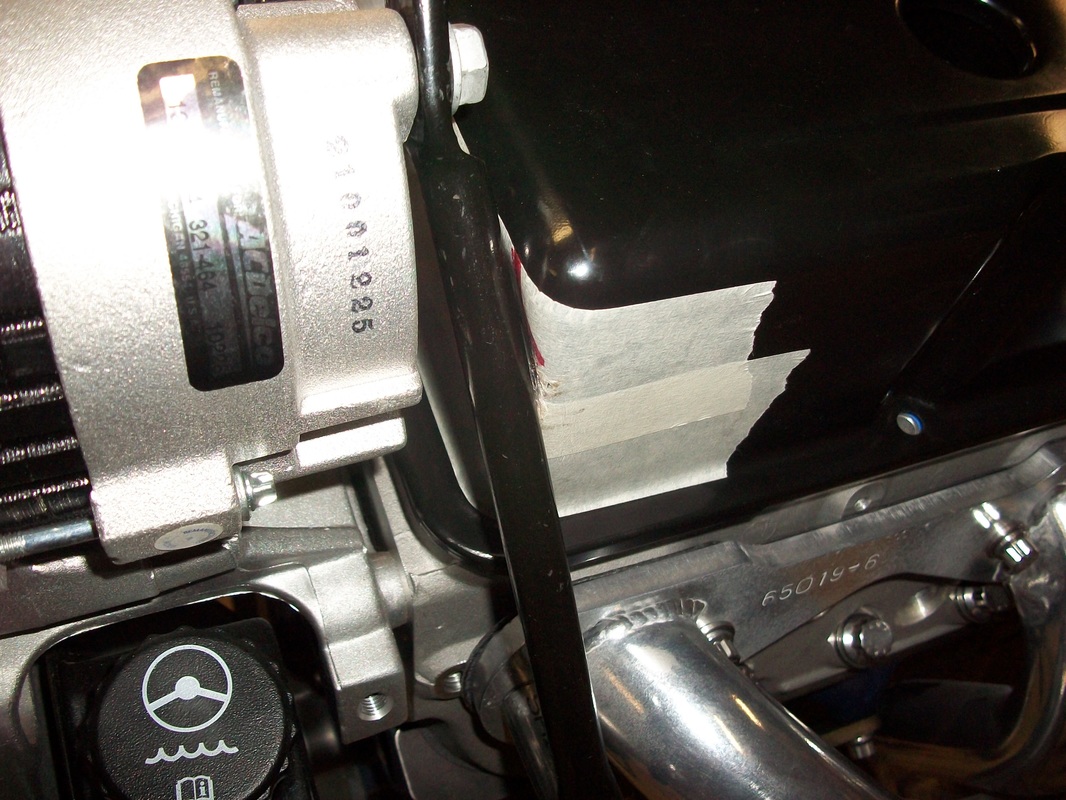

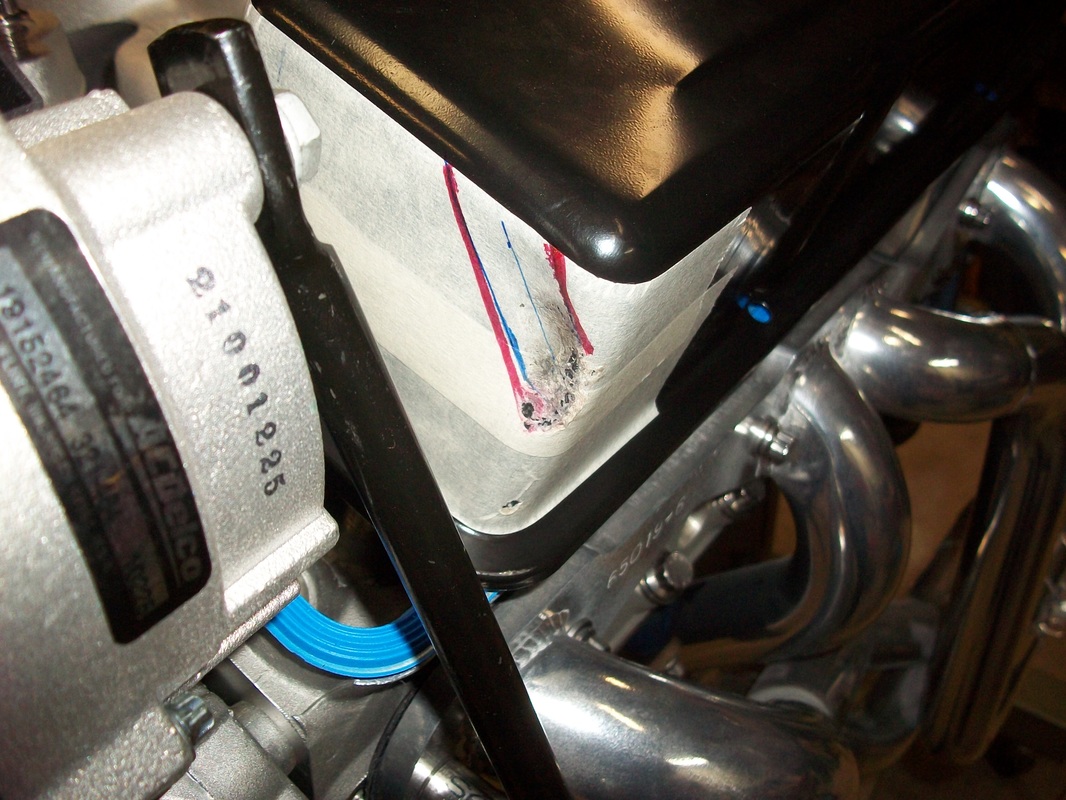

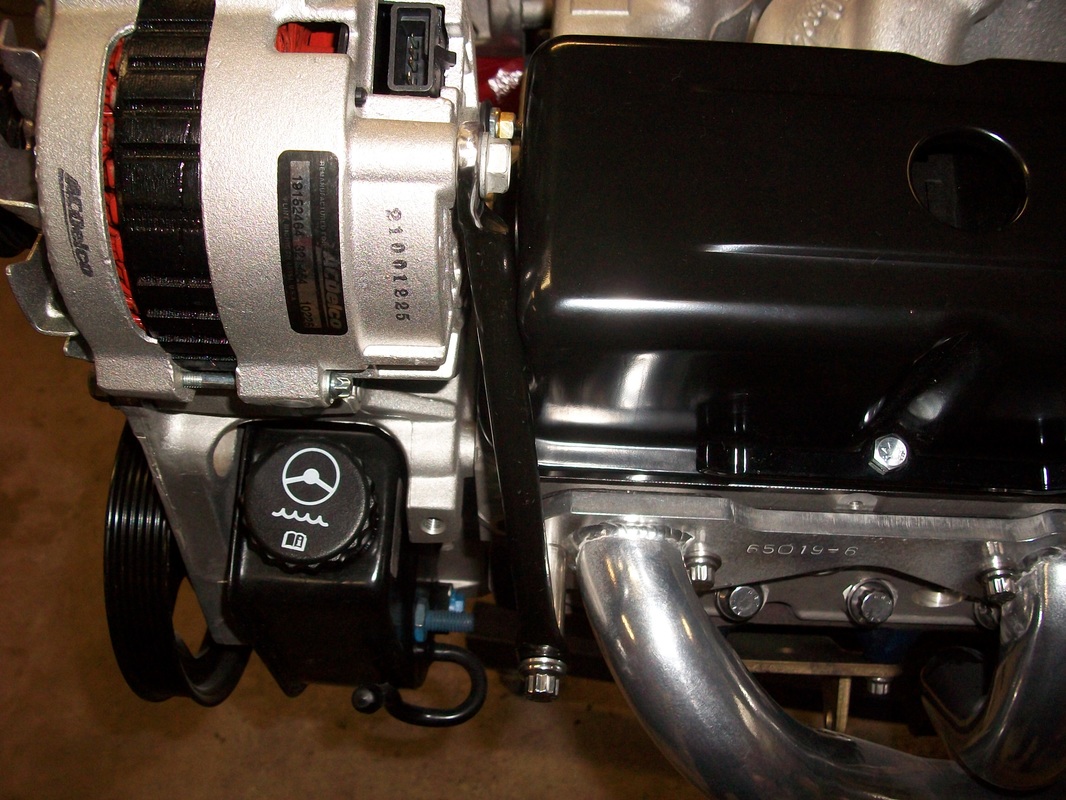

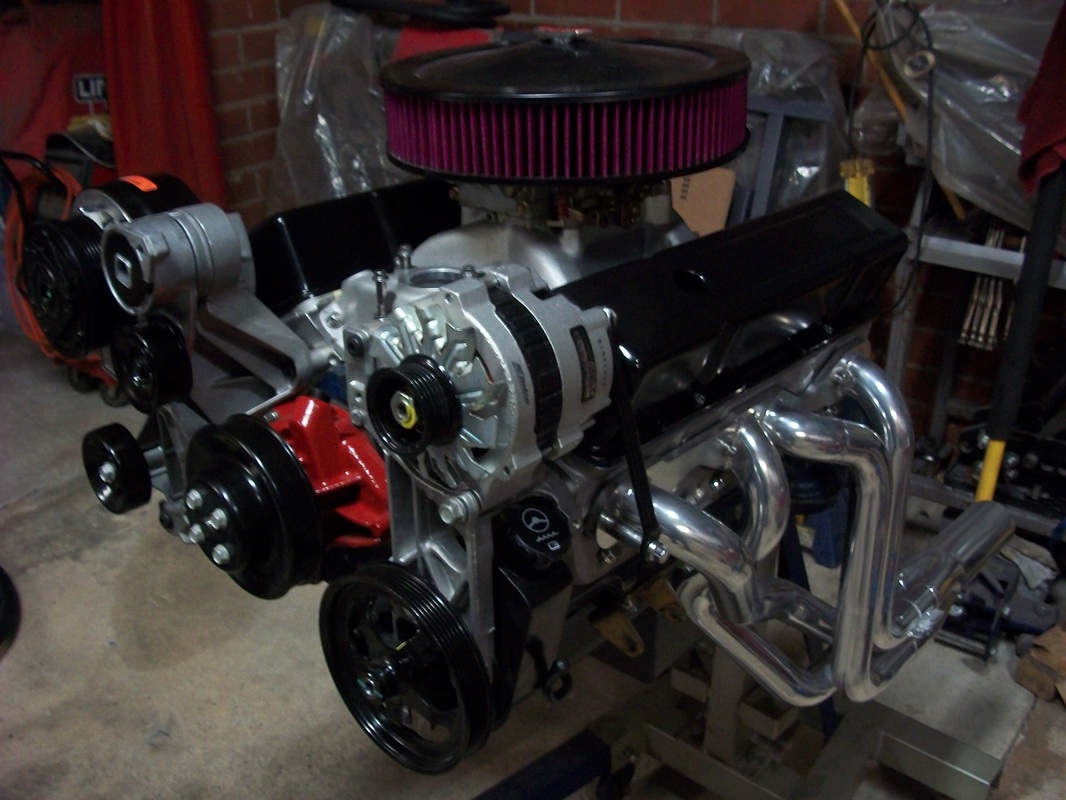

My internet guy has had his head down trying to get external engine modifications finished so that I can get the engine block to the machine shop as soon as possible. I had to make an A/C compressor bracket, and modify a valve cover for clearance from the alternator and alternator bracket. I also went ahead and marked the intake manifold and heads for port matching and modification of the water jackets. The polishing is still an ongoing event, but as of yet I have not hit anything with the white diamond.

The knuckles in the back ground still need to be polished, and as stated before, the front calipers still need sanding. You can see the difference between blasted, 400 grit sanded, 1000 grit sanded, and black emery polished in this picture.

|

Serial Machines

2711 Mooresville Rd Archives

May 2017

Categories |

|

|